In medical institutions such as hospitals and nursing homes, where beds are used intensively and the risk of cross-infection is high, Bed Unit Sterilizer (bed unit disinfection machine) has become a key device to ensure the hygiene of bed units. However, many medical staff and procurement personnel still have questions about its disinfection method, scope of application, and correct operation. The following will answer these practical questions by combining industry expertise and on-site application experience.

1. Disinfection Principle: How does Bed Unit Sterilizer achieve thorough disinfection of bed units? Is its disinfection effect affected by the material of bed sheets and quilts?

Bed Unit Sterilizer mainly uses two core disinfection technologies: UVC ultraviolet sterilization and ozone sterilization (some models also integrate plasma sterilization). When in use, the device's disinfection covers (or hoses) are spread over the bed unit (including mattresses, bed sheets, quilts, pillows, etc.), and the internal fan draws the air inside the bed unit into the disinfection chamber. First, UVC ultraviolet rays in the chamber destroy the DNA/RNA of bacteria, viruses, and mold spores in the air and on the surface of fabrics, inactivating them. At the same time, the ozone generator produces a certain concentration of ozone, which diffuses into the gaps of the bed unit (such as the inside of the mattress and the interlayer of the quilt) with the air flow. Ozone has strong oxidizing properties, which can further kill microorganisms hidden in the deep layers of the bed unit that are difficult to be irradiated by ultraviolet rays, achieving "surface + deep" dual sterilization.

A common concern is whether the material of bed sheets and quilts affects the disinfection effect. In fact, for most common fabrics (such as cotton, polyester, and cotton-polyester blends), the disinfection effect of the device is rarely affected. However, it should be noted that if the fabric is too thick (such as a thick cotton mattress with a thickness exceeding 15cm) or has a high density (such as a waterproof coating fabric), it may slow down the diffusion speed of ozone and the penetration of ultraviolet rays, thereby extending the required disinfection time. For example, for a standard thin bed sheet, a 30-minute disinfection cycle is sufficient; for a thick mattress, it may be necessary to extend the cycle to 45-60 minutes. In addition, dark-colored fabrics may absorb a small amount of ultraviolet rays, but the impact is negligible under the combined action of ozone. Therefore, when purchasing, you can confirm with the manufacturer whether the device is suitable for the specific fabric materials used in the institution.

2. Application Scenarios: Which medical institutions and departments have the most urgent need for Bed Unit Sterilizer? Are there any restrictions on its use in non-medical scenarios?

Bed Unit Sterilizer is most urgently needed in medical institutions with high bed turnover rates and high infection risks. In hospitals, general wards, infectious disease wards, and ICU (Intensive Care Unit) are the core application areas. In general wards, each bed is used by different patients in turn, and residual pathogens on the bed unit may cause cross-infection; in infectious disease wards, patients with tuberculosis, influenza, or new coronavirus may leave a large number of pathogens on the bed unit, requiring professional disinfection to prevent the spread; in the ICU, patients have weak immunity, and even low-concentration pathogens may cause severe infections, so the bed unit must be disinfected to a higher standard. In addition, nursing homes, rehabilitation centers, and community health service centers also have a great demand for this device, as the elderly and disabled groups in these places are more vulnerable to pathogenic microorganisms.

In non-medical scenarios, Bed Unit Sterilizer can also be used, but there are certain restrictions. For example, in hotels with high-end customer groups (such as five-star hotels) or homestays that focus on hygiene, it can be used to disinfect beds after guests check out, improving customer trust. However, it is not recommended for ordinary households. On the one hand, the frequency of bed use by family members is relatively fixed, and the risk of cross-infection is low, so ordinary sun exposure and washing can meet the hygiene needs; on the other hand, the device needs to be operated by professionals (to avoid ozone leakage and ultraviolet radiation), and the cost of household use is relatively high. In addition, in public places such as student dormitories and staff dormitories, if the bed turnover rate is low, it is more cost-effective to use regular cleaning and disinfection methods instead of purchasing Bed Unit Sterilizer.

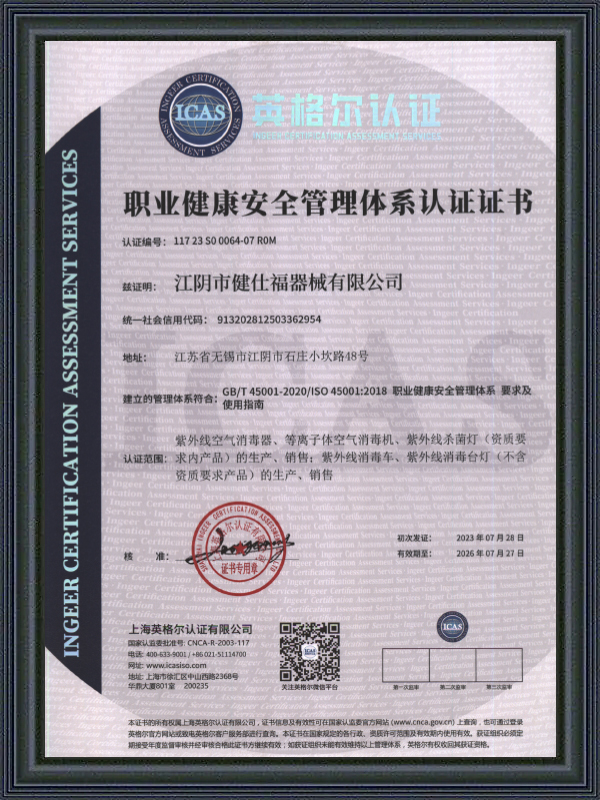

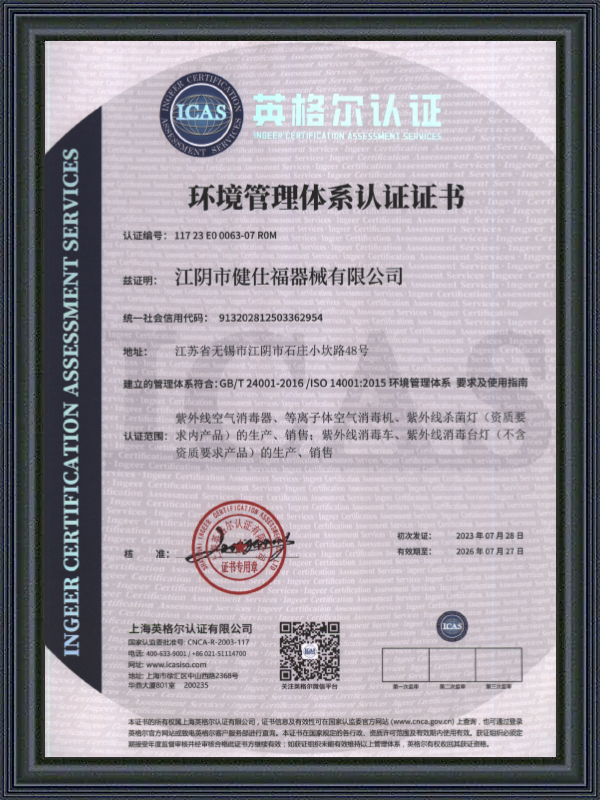

Enterprises like Jiangyin Jianshifu Equipment Co., Ltd., which have a complete product line of disinfection equipment, produce Bed Unit Sterilizers suitable for different scenarios. For example, they provide small mobile models for general wards (easy to move between beds) and large fixed models for ICUs (with higher disinfection efficiency). They can also provide customized solutions according to the number of beds and the size of the ward in the institution, ensuring that the disinfection needs of different departments are met.

3. Purchase Criteria: What performance indicators should be focused on when purchasing Bed Unit Sterilizer for different wards? How to distinguish between professional medical-grade models and ordinary models?

When purchasing Bed Unit Sterilizer, the key is to match the performance of the device with the infection risk level of the ward. The first core indicator is sterilization rate and scope. For general wards, the device only needs to achieve a sterilization rate of ≥99.9% for common bacteria (such as Escherichia coli and Staphylococcus aureus); for infectious disease wards and ICUs, it must also be effective against viruses (such as hepatitis B virus, new coronavirus) and drug-resistant bacteria (such as MRSA), with a sterilization rate of ≥99.99%. Therefore, when checking the product manual, it is necessary to confirm whether the device has passed the test for targeted pathogens.

The second indicator is ozone concentration and UV intensity. The ozone concentration in the disinfection space should be controlled between 0.3-0.5mg/m³ (the national standard for medical ozone disinfection). If the concentration is too low, the disinfection effect is insufficient; if it is too high, it may cause corrosion to the bed frame and fabric, and even cause respiratory discomfort to medical staff after leakage. The UV intensity (at a distance of 1m from the lamp) should be ≥70μW/cm², which ensures that the surface of the bed unit can be irradiated with effective ultraviolet rays. In addition, the device should be equipped with an ozone decomposition function—after disinfection, it can decompose the remaining ozone into oxygen within 10-15 minutes, avoiding harm to the human body when the bed is used again.

To distinguish between professional medical-grade models and ordinary models, the most direct method is to check the certification documents. Professional medical-grade Bed Unit Sterilizers must have the "Medical Device Registration Certificate" (Class II medical device) issued by the National Medical Products Administration, while ordinary models (such as household small disinfection machines) only have the "Disinfection Product Sanitary Safety Evaluation Report". In addition, medical-grade models have more humanized safety designs: for example, they are equipped with a "door opening and power-off" function (if the disinfection cover is accidentally opened during operation, the device will automatically shut down to prevent ozone leakage and ultraviolet radiation); the shell is made of flame-retardant ABS material (complying with medical fire safety standards), while ordinary models often use ordinary plastic shells. Manufacturers like Jiangyin Jianshifu Equipment Co., Ltd. can provide complete certification documents for their medical-grade Bed Unit Sterilizers, and their sales staff have professional medical knowledge to help customers distinguish between different levels of models.

4. Operation Guidelines: How to standardize the operation process of Bed Unit Sterilizer to avoid safety risks? What common operational errors need to be prevented?

The standardized operation of Bed Unit Sterilizer is crucial to ensuring disinfection effect and avoiding safety risks. The correct process is as follows: First, preparation before disinfection: Remove all personal items (such as mobile phones, books, and clothes) from the bed unit, smooth out bed sheets and quilts (avoiding folds that block ozone diffusion), and check whether the device's disinfection cover is intact (no cracks or air leaks). Second, equipment connection: Spread the disinfection cover over the bed unit, connect the cover to the main machine with a hose, and close the door and window of the ward (to prevent ozone leakage). Third, parameter setting: According to the type of bed unit (such as a single bed or a double bed) and the fabric thickness, set the disinfection time (usually 30-60 minutes) and start the device. Fourth, post-disinfection treatment: After the disinfection is completed, wait for the device to decompose ozone (until the ozone smell disappears), then open the door and window for ventilation for 10 minutes before allowing patients to use the bed.

There are three common operational errors that need to be strictly prevented. First, ignoring the inspection of the disinfection cover: If the cover has a crack, ozone will leak during operation, reducing the disinfection effect and causing respiratory irritation to medical staff in the ward. Therefore, it is necessary to check the cover for damage before each use. Second, shortening the disinfection time: In order to speed up the bed turnover, some medical staff may reduce the disinfection time from 45 minutes to 20 minutes. This will lead to insufficient ozone concentration and ultraviolet irradiation time, resulting in incomplete disinfection. Third, allowing personnel to enter the ward during disinfection: Ozone has a pungent smell, and long-term exposure to ozone with a concentration exceeding 0.1mg/m³ can damage the respiratory tract. Therefore, during the disinfection process, it is necessary to hang a "disinfection in progress, no entry" sign outside the ward, and no one is allowed to enter except for emergency situations.

5. Maintenance and After-sales: How to maintain Bed Unit Sterilizer to ensure its long-term stable operation? What should be done if the device alarms during use?

Daily maintenance of Bed Unit Sterilizer mainly focuses on three parts: disinfection cover maintenance, internal component maintenance, and regular performance testing. For the disinfection cover, it should be cleaned once a week—wipe the surface with a neutral detergent (avoiding corrosive cleaning agents like bleach) and dry it in a cool place (not exposing it to the sun, which may age the fabric). If the cover is seriously worn (such as a large area of fabric damage), it should be replaced immediately to prevent ozone leakage. For internal components, the air filter of the main machine should be cleaned every two weeks (remove the filter, tap it gently to remove dust, or rinse it with clean water and dry it); the UV lamp should be checked monthly—if the lamp turns yellow or the brightness decreases significantly, it means the lamp is aging and needs to be replaced (the service life of the UV lamp is usually 5,000-8,000 hours).

Regular performance testing is also essential. It is recommended to conduct a "disinfection effect test" every 3 months: use a bacterial culture dish to sample the surface of the bed unit before and after disinfection, and send it to a professional testing institution to detect the sterilization rate. If the rate is lower than 99%, it is necessary to check whether the ozone concentration and UV intensity meet the standards. At the same time, an "ozone leakage test" should be conducted every 6 months: use an ozone detector to detect the concentration of ozone in the ward during disinfection, and if the leakage concentration exceeds 0.05mg/m³, it is necessary to check whether the disinfection cover and hose are sealed properly.

If the device alarms during use, it is necessary to troubleshoot according to the alarm type. Common alarms include ozone concentration abnormal alarm and UV lamp failure alarm. If it is an ozone concentration abnormal alarm, first turn off the device and check whether the disinfection cover is tightly connected to the main machine (loose connection may cause ozone leakage, leading to low internal concentration); if the connection is normal, it may be that the ozone generator is faulty, and the manufacturer's after-sales personnel should be contacted for repair. If it is a UV lamp failure alarm, turn off the power and check whether the lamp is loose or broken—if it is loose, reinsert it firmly; if it is broken, replace it with a new lamp of the same model.

Enterprises like Jiangyin Jianshifu Equipment Co., Ltd. provide comprehensive after-sales services for Bed Unit Sterilizer. They not only provide free operational training for medical staff when delivering the device but also send technicians to conduct on-site maintenance and performance testing every year. If the device fails, their after-sales team can provide remote guidance within 2 hours (helping to troubleshoot simple faults) or send personnel to the site for repair within 24 hours (for complex faults), ensuring that the device can be restored to normal operation as soon as possible.

English

English  عربى

عربى

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China sara@jsf-qx.com

sara@jsf-qx.com +86-18915253915

+86-18915253915 +86-18861287595

+86-18861287595