1. Product Definition and Core Value

An Examination Lamp is a specialized lighting device designed to provide directional illumination for professional inspection, diagnosis, and precision operations. Its core value lies in accurately controlling lighting parameters to eliminate visual interference, enabling users to capture subtle features or complete delicate tasks. This equipment plays an irreplaceable role in multiple fields such as healthcare, industrial quality inspection, and laboratory analysis.

In the healthcare sector, for instance, during a dermatological diagnosis, an Examination Lamp with high color rendering index can accurately present the color, texture, and boundary of skin lesions, helping doctors distinguish between benign and malignant conditions. In industrial quality inspection, when examining the surface of precision electronic components, the lamp's uniform light distribution ensures that even tiny scratches or solder joint defects are not overlooked. As a crucial part of professional equipment, the performance of an Examination Lamp directly affects the accuracy of detection and operational safety, thus strict compliance with industry standards and scenario - specific requirements is essential in its design and production.

2. Main Classifications and Application Scenarios

The classification system of Examination Lamps is established based on application scenarios and functional characteristics. Different types of products have significant differences in parameter configurations to adapt to diverse usage needs.

2.1 Examination Lamps for the Healthcare Field

This is the most technically demanding category of Examination Lamps, covering a variety of specialized uses:

Operating Room Shadowless Lamps: These lamps achieve a shadow - free degree of ≥90% through multi - light source superposition and optical design. The light intensity can reach 160,000 - 200,000 Lux, and the spot diameter is adjustable from 15 to 30 cm, providing uniform, shadow - free surgical field illumination for surgical operations. During open - heart surgery, for example, the shadowless feature ensures that every detail of the heart and blood vessels is clearly visible, allowing surgeons to perform precise suturing and vascular anastomosis.

Department - Specific Diagnostic Lamps: Including dental diagnostic lamps, ophthalmic examination lamps, and dermatological examination lamps. Ophthalmic examination lamps must comply with the ISO 15004 test standard to ensure accurate observation of the fundus, cornea, and other eye structures. Dermatological examination lamps, on the other hand, need to precisely control the color temperature to restore the characteristics of skin lesions. For instance, in the diagnosis of psoriasis, a dermatological examination lamp with appropriate color temperature can clearly show the silver - white scales and red patches of the lesion.

Mobile Emergency Examination Lamps: These lamps are portable and have wireless power supply capabilities, making them suitable for first - aid scenes, ward rounds, and other situations. Some products meet the IP54 waterproof and dustproof level, enabling them to be used in complex environments such as outdoor emergency rescues in rainy weather or dusty disaster areas.

Endoscope Light Sources: As cold light source devices, they illuminate the internal organs of the human body through optical fiber transmission. Some are equipped with fluorescence excitation functions to assist in the diagnosis of lesions and avoid thermal radiation damage to tissues. During gastrointestinal endoscopy, the endoscope light source provides sufficient and soft light, allowing doctors to clearly observe the mucosal surface of the digestive tract and detect early tumors or ulcers.

2.2 Examination Lamps for Industrial and Laboratory Use

Precision Inspection Lamps: Such as annular LED lamps and magnifying inspection lamps. Through the design of high - uniformity light spots (with an unevenness of less than 15%), they help detect subtle defects in electronic components and precision parts. When inspecting the welding points of integrated circuits, the annular LED lamp surrounds the component, ensuring that each welding point is evenly illuminated, making it easy to find false welding or cold welding problems.

Laboratory Analysis Lamps: These lamps need to meet specific spectral requirements. Some are equipped with ultraviolet or infrared bands to adapt to scenarios such as chemical analysis and biological sample observation. Moreover, they must pass electromagnetic compatibility tests to ensure stable coexistence with other laboratory instruments. In biological laboratories, when observing cell cultures, laboratory analysis lamps with appropriate spectral characteristics can help researchers clearly see the morphology and growth status of cells.

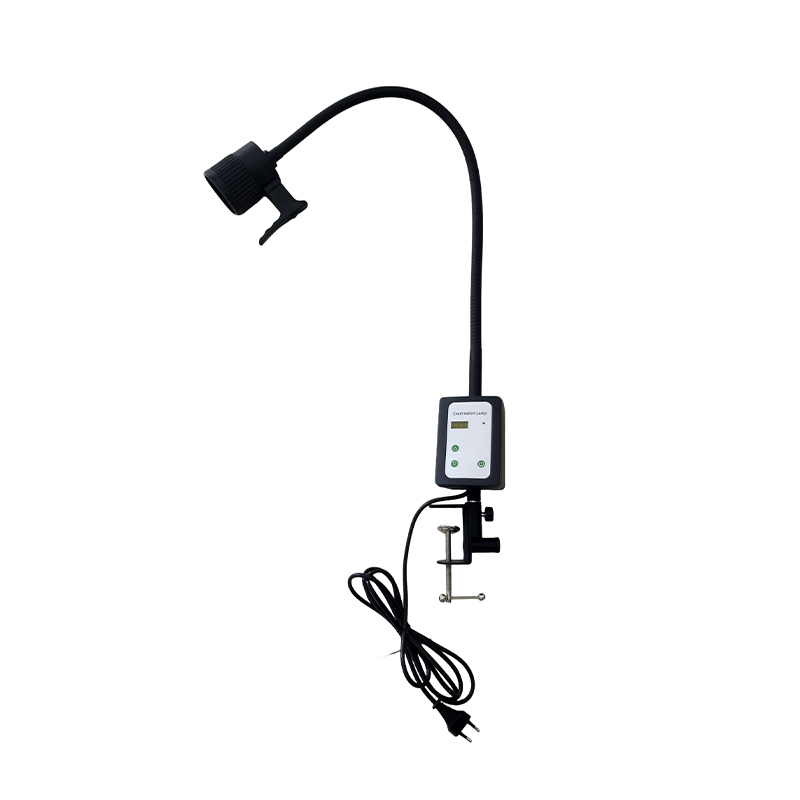

Jiangyin Jianshifu Equipment Co., Ltd., which has been deeply engaged in the disinfection equipment field for many years, also includes Examination Lamps in its product line. This complements its other products such as plasma air sterilizers and UV germicidal lamps, meeting the comprehensive equipment needs in healthcare and other scenarios. The company's modern production lines and professional testing equipment lay a solid foundation for the quality of Examination Lamps.

3. Core Technical Parameters and Performance Standards

The performance evaluation of Examination Lamps focuses on three core dimensions: optical performance, electrical safety, and mechanical characteristics. Each parameter is constrained by clear industry standards.

3.1 Core Optical Performance Parameters

Illuminance: It ranges from 0 to 100,000 Lux according to scenario requirements. Products for surgical use require higher illuminance, with some reaching up to 200,000 Lux. Additionally, the variation range of light output stability should be less than 5%. In neurosurgery, where high - precision operations are required, stable and high illuminance ensures that surgeons can clearly see the fine structures of the brain, reducing the risk of operational errors.

Color Temperature and Color Rendering Index: The standard color temperature range is 3000 - 6700K, which can be adjusted according to needs (for example, neurosurgery prefers cool white light, while gynecology often uses warm white light). The color rendering index (Ra value) must be ≥95 to accurately restore the true color of objects, which is crucial for tissue identification in medical diagnosis. For example, when distinguishing between different types of tissues during surgery, a high color rendering index helps doctors accurately identify blood vessels, nerves, and other tissues, avoiding accidental injury.

Light Distribution Characteristics: This includes spot uniformity (unevenness < 15%) and light distribution angle (angle error < 5 degrees), which are optimized through multi - surface reflector technology and optical array design. In industrial inspection, uniform light distribution ensures that every part of the inspected object is illuminated consistently, preventing missed detections due to uneven lighting.

3.2 Safety and Reliability Indicators

Electrical Safety: The insulation resistance should be greater than 100MΩ, the ground continuity resistance less than 0.1Ω, the leakage current ≤0.5mA under normal conditions, and ≤1mA under a single fault. These requirements comply with medical electrical equipment safety standards such as GB 9706.1. Strict electrical safety standards ensure that the lamp does not pose an electric shock risk to users during use, especially in healthcare settings where patients and medical staff are in close contact with the equipment.

Thermal Safety: The maximum surface temperature should be lower than 40℃, and the skin temperature rise at a distance of 50cm should be ≤3℃ to avoid burns caused by thermal radiation. The cold - light characteristic of LED light sources gives them a natural advantage in this aspect. In long - term surgical operations, the low surface temperature of the lamp prevents medical staff from being scalded when approaching the lamp, and also avoids thermal damage to the patient's body tissues.

Durability: The mechanical impact strength should be able to withstand an energy impact of 50J, and the joint braking system should be able to bear a load of 500N without displacement. The average service life of the light source is usually ≥10,000 hours, and that of LED - type products can reach more than 50,000 hours. In high - frequency use scenarios such as large hospitals, the durability of the lamp reduces the frequency of equipment replacement, saving maintenance costs.

3.3 Main Implementation Standards

A comprehensive standard system has been established both internationally and domestically, including the safety requirements for medical electrical equipment ISO 60601 - 2 - 41, the general safety standard IEC 60601 - 1, and the Chinese medical equipment safety standard GB 9706.1. These standards ensure the performance and safety of the products. Compliance with these standards is not only a requirement for entering the market but also a guarantee for the stable and safe operation of the equipment in various application scenarios.

4. Industry Technology Development Trends

With the advancement of optical technology and electronic control technology, and the deepening of application needs, the Examination Lamp industry is evolving in the direction of intelligence, specialization, and greenization.

4.1 Light Source Technology Iteration

LED light sources have fully replaced traditional halogen lamps and xenon lamps as the mainstream. They have the advantages of low power consumption (power consumption ranging from 10 to 500W), long service life, adjustable color temperature, and no thermal radiation. Some high - end products adopt imported German LED chips and patented reflection technology to further improve optical performance. For example, the use of high - quality LED chips can enhance the stability of light output and the accuracy of color rendering, making the lamp more suitable for high - precision application scenarios.

4.2 Intelligent Function Upgrades

Intelligent Examination Lamps integrated with artificial intelligence and image recognition technology are gradually emerging. They have functions such as automatic light compensation, target tracking, and image enhancement. Some products support touch control (with a response time of ≤0.5s) and voice commands (with a recognition rate of ≥95%), enabling 10% - 100% multi - level dimming or stepless dimming. In healthcare settings, automatic light compensation can adjust the illuminance and color temperature in real - time according to changes in the surgical field or the position of the patient, ensuring that doctors always have the best viewing conditions. Voice control allows doctors to adjust the lamp's parameters without touching the equipment, reducing the risk of cross - infection.

4.3 Deepening of Scenario Adaptation

Specialized segmentation has become an important trend. Products such as cold light source lamps for minimally invasive surgery, annular LED lamps for precision part inspection, and portable wireless lamps for mobile healthcare are constantly emerging to meet the personalized needs of different scenarios. For minimally invasive surgery, cold light source lamps with small size and flexible light transmission can be easily integrated into minimally invasive surgical instruments, providing sufficient illumination for the internal surgical field. Portable wireless lamps for mobile healthcare are convenient for medical staff to carry to remote areas or home healthcare scenarios, expanding the scope of medical services.

4.4 Green and Environmental - Friendly Design

The application of low - power LED chips, replaceable battery modules, and recyclable shell materials is becoming increasingly widespread. At the same time, through the optimization of heat dissipation structures and circuit designs, energy consumption is further reduced, in line with the concept of energy conservation and environmental protection. The use of recyclable materials reduces the environmental impact of product waste, and low energy consumption helps reduce the overall energy consumption of medical institutions and industrial enterprises, contributing to the achievement of global energy conservation and emission reduction goals.

5. Core Industry Challenges and Quality Control

Currently, the industry still faces some challenges. Low - end products have shortcomings in light intensity uniformity, heat dissipation performance, and waterproof level. Differences in standards across different industries lead to low product standardization, which brings difficulties to procurement and use.

To address these challenges, professional manufacturers generally establish strict quality control systems. For example, enterprises like Jiangyin Jianshifu Equipment Co., Ltd. ensure that their products meet industry standards and meet the diverse needs of different scenarios by equipping modern production lines and professional testing equipment, and conducting comprehensive testing of optical performance, electrical safety, and mechanical characteristics in conjunction with third - party testing institutions.

In terms of quality control during the production process, manufacturers implement strict incoming inspection of raw materials to ensure that only high - quality components are used. During the production process, they carry out real - time monitoring of key processes to prevent defects from occurring. After the product is manufactured, a series of strict tests are conducted, including optical performance testing, electrical safety testing, and durability testing, to ensure that each product leaving the factory meets the required standards.

For users such as medical institutions, they establish a three - level system of daily inspection, quarterly functional testing, and annual comprehensive testing to ensure the continuous and stable operation of the equipment. Daily inspection mainly includes checking the appearance of the lamp, the normal operation of the switch, and the stability of the light output.

Quarterly functional testing involves testing parameters such as illuminance, color temperature, and color rendering index to ensure that the lamp's performance meets the application requirements. Annual comprehensive testing covers all aspects of the lamp, including electrical safety, mechanical performance, and optical performance, to identify potential problems in a timely manner and carry out maintenance or replacement.

In addition, the industry also needs to strengthen the unification of standards. Relevant government departments and industry associations should work together to formulate more unified and strict industry standards, reducing differences in standards across different regions and industries. This will help improve the overall quality level of the industry, facilitate the procurement and use of products by users, and promote the healthy and sustainable development of the Examination Lamp industry.

English

English  عربى

عربى

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China sara@jsf-qx.com

sara@jsf-qx.com +86-18915253915

+86-18915253915 +86-18861287595

+86-18861287595