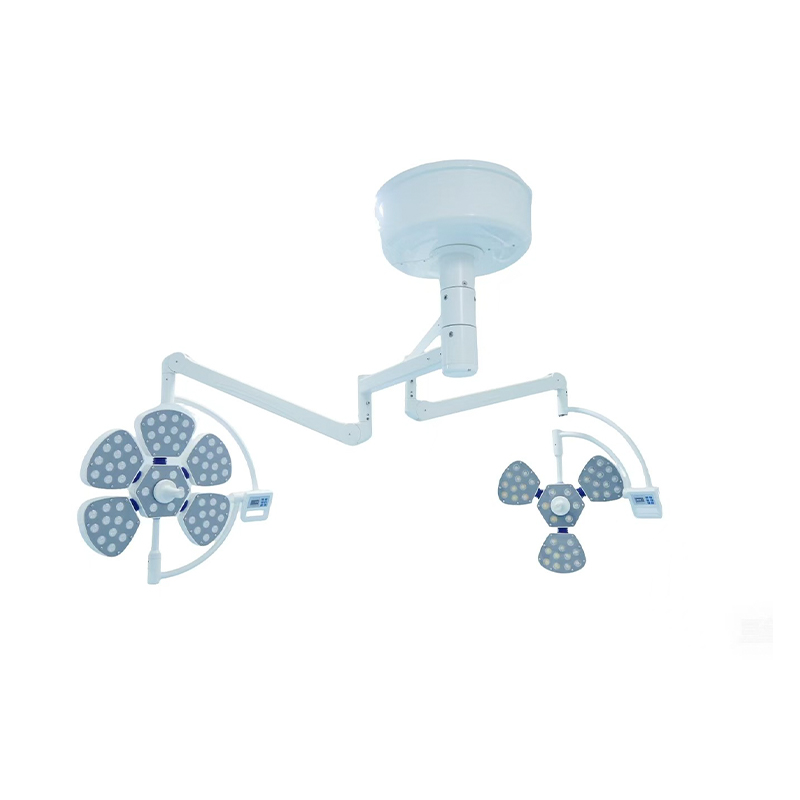

In medical scenarios, the Operating Light is one of the core equipment ensuring precise operations. Its role goes far beyond basic lighting; through professional design, it provides a clear, shadow-free, and stable lighting environment for the surgical area, directly affecting the safety and accuracy of operations. As an enterprise deeply engaged in the medical equipment field, Jiangyin Jianshifu Equipment Co., Ltd., founded in 1993, also includes such medical lighting equipment in its product line. Together with plasma air sterilizers, bed unit sterilizers, and other products, it meets the diverse needs of medical scenarios.

Core Working Principles

The core advantage of the operating light stems from the combination of the multi-point light source effect and optical optimization technology. Its basic principle is that multiple light sources illuminate the surgical area simultaneously from different angles. When part of the light is blocked by surgical instruments or the bodies of medical staff, light from other angles can fill the shadowed area, ultimately forming a uniform shadow-free zone. Modern equipment has been further upgraded based on this:

- Integral Reflection Technology: Through a composite curved reflector composed of thousands of small planes, light is efficiently concentrated and evenly distributed, reducing light spots and residual shadows;

- Cold Light Technology: With the help of a special optical system or LED cold light source, thermal radiation such as infrared rays is isolated, avoiding the drying of tissues in the surgical area and visual fatigue of medical staff;

- Intelligent Compensation Function: Some equipment can monitor the light intensity in real-time and automatically adjust when the light source is worn out to maintain a stable lighting effect.

Main Classifications and Applicable Scenarios

According to the installation method and functional requirements, operating lights can be divided into different types to adapt to various medical scenarios:

Classification by Installation Method

- Mobile Operating Lights: Supported by a floor stand with rollers, they can move freely indoors. They are suitable for scenarios where the surgical position changes frequently, such as temporary operating rooms or small clinics;

- Ceiling-mounted Operating Lights: Fixed to the ceiling or wall via a suspension rod, they do not occupy floor space. The light can be adjusted in all directions, making them the mainstream choice for comprehensive operating rooms;

- Wall-mounted Operating Lights: Directly installed on the wall, they are suitable for small specialist clinics or auxiliary treatment areas, such as dental treatment rooms and ophthalmology examination rooms.

Classification by Functional Requirements

- Single-head Operating Lights: With only one lamp head, the light range is concentrated. They are suitable for small outpatient surgeries or local fine operations;

- Dual-head Operating Lights: The main lamp provides core lighting, and the auxiliary lamp fills the blind area. The overlapping range of light spots can be flexibly adjusted to meet the needs of most operations such as general surgery and gynecology, becoming the mainstream configuration in hospitals;

- Multi-head Operating Lights: Multiple lamp heads work together to cover a wider lighting area, suitable for large and complex operations such as neurosurgery and cardiovascular surgery.

In addition to operating rooms, such equipment is also widely used in scenarios such as ophthalmology examinations and dental root canal treatments, providing the necessary clear vision for fine operations.

Key Selection Indicators

When selecting an operating light, the following core performance parameters should be focused on to ensure it meets actual usage needs:

Lighting Performance

- Brightness and Adjustability: It needs to meet the requirements of different types of operations. For example, deeper operations require higher brightness, and the brightness should support stepless adjustment to avoid eye irritation from strong light;

- Light Uniformity: The brightness difference in the surgical area should be controlled within a very small range to prevent affecting tissue observation due to uneven light and shadow;

- Shadow-free Effect: The shadow-free rate of professional equipment should reach more than 90%, which can be judged through an occlusion test - using a hand to simulate occlusion in the light area and observing the speed and thoroughness of shadow fading.

Safety and Adaptability

- Electrical Safety: It must comply with medical equipment electrical standards, have overload protection and leakage protection functions, and the power cord must meet the medical insulation level to reduce the risk of fire and electric shock;

- Heat Dissipation Performance: The surface temperature of the equipment should be below the safety threshold during long-term operation to avoid the risk of scalding and extend the service life;

- Flexibility and Stability: The mechanical arm should support 360° rotation, and the lamp head can be tilted and positioned freely without shaking after adjustment, ensuring the accurate and stable lighting angle during the operation.

Convenience of Cleaning and Maintenance

The lamp body shell should be made of corrosion-resistant and easy-to-wipe materials, and the lamp head and handle should be designed as detachable structures to facilitate disinfection with 70%-80% ethanol solution after the operation, meeting the hygiene requirements of medical scenarios.

Daily Use and Maintenance Specifications

Standardized operation and maintenance are the keys to ensuring the performance of the equipment. The core points include:

Daily Cleaning and Disinfection

- After each operation, the power should be cut off, and a soft cloth dipped in 70%-80% ethanol solution should be used to wipe the surface of the lamp body (avoiding the light-emitting surface). Wipe twice, and the action time should be no less than 3 minutes;

- The light-transmitting glass should be gently cleaned with medical gauze. Hard brushes, acid-base solvents, etc., should not be used to prevent scratching or corrosion;

- For equipment with an external camera system, the dust and moisture in the interface holes should be regularly removed to reduce the risk of leakage.

Regular Professional Inspection

It is recommended that professional personnel conduct a comprehensive inspection every two months, focusing on:

- Whether the fasteners of the ceiling or bracket are loose;

- Whether the line connection is good and whether there is aging and damage;

- Whether the mechanical arm moves flexibly and the positioning is accurate;

- Whether the light source brightness meets the standard and whether the backup bulb can switch automatically.

Special Environment Protection

In high-temperature and high-humidity environments in summer, it is necessary to strengthen the heat dissipation and moisture-proof of the equipment: ventilation holes can be set around the ceiling, and electronic equipment can be put on standby regularly to drive away moisture in humid weather, and avoid installation in positions prone to moisture return such as corners.

The stable performance of the operating light is directly related to the medical quality. The professionalism in its selection, use, and maintenance is not only the basic requirement of the medical equipment industry but also the core consideration for enterprises like Jianshifu in the medical equipment field.

English

English  عربى

عربى

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China sara@jsf-qx.com

sara@jsf-qx.com +86-18915253915

+86-18915253915 +86-18861287595

+86-18861287595