Exploring Electric Suction Apparatus: Principles, Applications and Safety

I. What is an Electric Suction Apparatus?

An electric suction apparatus is a specialized medical device designed to create negative pressure (suction) for removing fluids, secretions, or foreign substances from the human body or specific environments. Unlike manual suction tools that rely on human force, electric suction apparatuses use an electric motor to drive a vacuum pump, generating stable and adjustable negative pressure—making them more efficient, consistent, and suitable for long-term or high-demand use.

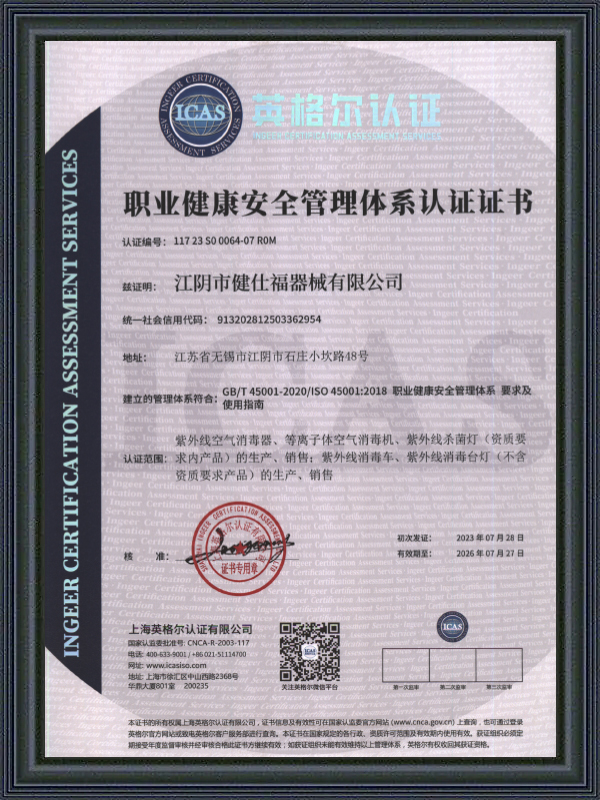

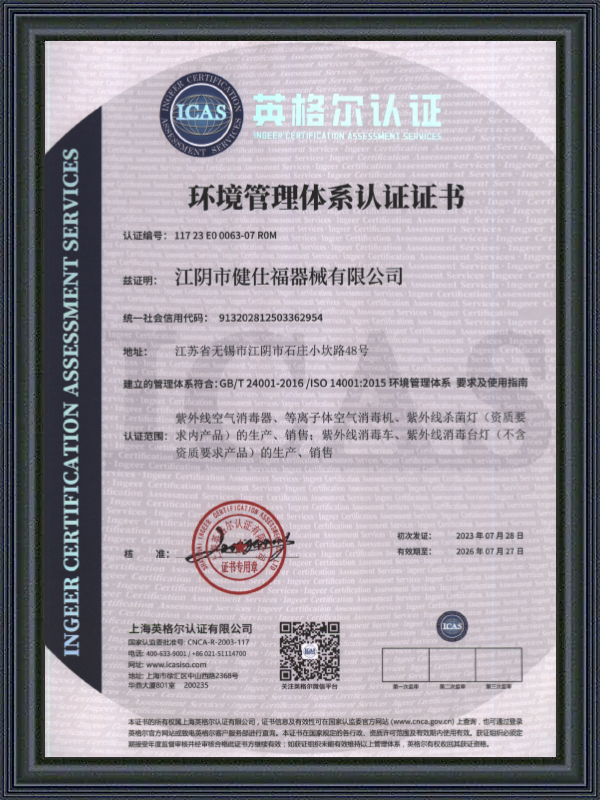

Common types include medical electric suction apparatuses (for clinical use, such as removing respiratory secretions or surgical fluids) and industrial electric suction apparatuses (for cleaning or waste collection in workshops). The focus here is on medical-grade models, which must meet strict safety and hygiene standards (e.g., leak-proof design, easy disinfection) to avoid cross-contamination or tissue damage. For professional equipment manufacturers like Jiangyin Jianshifu Equipment Co., Ltd. —a disinfection equipment specialist founded in 1993 and located in the New Material Industrial Park of Jiangyin Economic Development Zone—while its core product range includes plasma air sterilizers, bed unit sterilizers, and UV germicidal devices, the company’s expertise in medical equipment production (such as adhering to clinical safety standards and precision manufacturing) aligns with the technical requirements of electric suction apparatuses, ensuring compliance with healthcare regulations.

II. How Does an Electric Suction Apparatus Work?

The operation of an electric suction apparatus relies on a closed system that generates and controls negative pressure, with four core components working together:

1. Vacuum Pump (Power Core)

Driven by an electric motor, the vacuum pump reduces the air pressure inside the system to create negative pressure. Medical-grade models typically use oil-free vacuum pumps (to avoid oil contamination) or diaphragm pumps (for quieter operation and easier maintenance), ensuring the suction force is stable and free from impurities.

2. Pressure Regulator and Gauge

A built-in pressure regulator allows users to adjust the negative pressure according to specific needs (e.g., lower pressure for delicate respiratory suction, higher pressure for surgical fluid removal). The pressure gauge displays real-time pressure values (usually in kPa or mmHg), enabling precise control to prevent over-suction (which may damage tissues) or under-suction (which fails to remove fluids effectively).

3. Collection Container

Fluids or secretions sucked into the system are stored in a sealed collection container. Medical models often use transparent, graduated containers (allowing visual monitoring of fluid volume) and are equipped with anti-backflow valves—critical for preventing collected fluids from flowing back into the vacuum pump or the patient’s body, thus avoiding infection risks.

4. Suction Tube and Probe

Flexible suction tubes connect the collection container to disposable or sterilizable probes (e.g., nasal/oral suction catheters for respiratory use, surgical suction tips for operating rooms). These probes are designed for different body parts: for example, fine catheters for pediatric patients or larger tips for surgical bleeding control.

III. What Are the Application Scenarios of Electric Suction Apparatuses?

Electric suction apparatuses are indispensable in medical settings due to their ability to maintain airway patency, prevent infection, and support clinical procedures. Key application scenarios include:

1. Hospitals and Clinics

Respiratory Care: Used for patients with difficulty clearing secretions on their own, such as those with pneumonia, asthma, or post-anesthesia recovery. For example, intubated patients (on mechanical ventilation) require regular suction of tracheal secretions to avoid airway blockage.

Surgical Procedures: Essential in operating rooms for removing blood, tissue fluids, or irrigation solutions during surgeries (e.g., abdominal surgery, orthopedic surgery). This keeps the surgical field clear, reduces infection risks, and improves operation accuracy.

Emergency Medicine: Critical for treating patients with airway obstructions (e.g., choking on vomit, foreign bodies) or trauma (e.g., severe nasal bleeding). Emergency medical teams often carry portable electric suction apparatuses for on-site rescue.

2. Nursing Homes and Home Care

For bedridden elderly patients or those with chronic conditions (e.g., advanced Parkinson’s disease, stroke) who cannot cough up secretions. Portable electric suction apparatuses (smaller in size, with rechargeable batteries) allow caregivers to provide timely suction at home, reducing hospital readmission rates.

3. Specialized Medical Settings

Dental Clinics: Used to remove saliva, blood, or dental materials (e.g., filling composites) during treatments, keeping the oral cavity dry and improving treatment efficiency.

Veterinary Hospitals: Similar to human medical use, for removing respiratory secretions or surgical fluids in animals (e.g., dogs, cats) undergoing treatment or surgery.

For Jiangyin Jianshifu Equipment Co., Ltd., which already serves medical settings with bed unit sterilizers and UV air sterilizers, electric suction apparatuses can complement its medical equipment portfolio—providing a one-stop solution for clinical disinfection and patient care needs.

IV. What Precautions Should Be Taken When Using an Electric Suction Apparatus?

Improper use of electric suction apparatuses may cause tissue damage, infection, or equipment failure. Follow these critical safety guidelines:

1. Pre-Use Inspection

Check the device for damage: Inspect the power cord (for fraying or cracks), vacuum pump (for abnormal noise), and suction tubes/probes (for blockages or leaks). For medical models, ensure all components are sterilized (or disposable parts are unopened) to avoid cross-contamination.

Test negative pressure: Turn on the device, adjust the pressure to the required range, and block the suction probe—if the pressure gauge remains stable, the system is leak-free; if pressure drops rapidly, check for tube disconnections or container seal issues.

2. Correct Operation for Medical Use

Adjust Pressure Appropriately: For adults, the recommended negative pressure is 40-80 kPa (300-600 mmHg) for respiratory suction; for infants and children, reduce to 20-40 kPa (150-300 mmHg) to avoid damaging delicate tissues. Never exceed the maximum pressure specified by the manufacturer.

Control Suction Time: Each suction session should last no more than 10-15 seconds, with a 1-2 minute interval between sessions. Prolonged suction can cause hypoxia (low oxygen levels) or tissue irritation.

Avoid Tissue Damage: Insert the suction probe gently (especially for nasal/oral suction) to prevent injury to the mucosa. Do not apply suction while inserting the probe—only start suction when the probe reaches the target area.

3. Post-Use Cleaning and Disinfection

Dispose of Disposable Parts: Discard used suction tubes, probes, and collection containers (if disposable) in medical waste bins. Reusable parts (e.g., the vacuum pump’s filter) should be cleaned and disinfected according to the manufacturer’s instructions (e.g., soaking in medical disinfectant, autoclaving).

Clean the Device Body: Wipe the exterior of the device with a disinfectant wipe (compatible with the device’s material, e.g., alcohol-free wipes for plastic surfaces) to remove blood or fluid residues.

4. Special Populations and Environments

For patients with fragile tissues (e.g., premature infants, elderly with thin nasal mucosa), use ultra-soft probes and lower pressure, and monitor for signs of bleeding (e.g., blood in suctioned fluids).

In flammable environments (e.g., operating rooms with laser equipment), use explosion-proof electric suction apparatuses to avoid fire risks.

V. How Do Electric Suction Apparatuses Differ from Similar Devices?

Electric suction apparatuses are often confused with other fluid-handling devices, but they differ in principle, design, and application:

Device Type

Core Principle

Key Difference from Electric Suction Apparatuses

Manual Suction Bulbs

Uses manual squeezing to create temporary negative pressure

Low suction force, inconsistent pressure, and suitable only for emergency or low-demand use (e.g., removing nasal secretions in infants). Electric models offer stable pressure and long-term use.

Vacuum Cleaners

Uses high negative pressure to suck dust and debris (industrial/home use)

Designed for non-medical use, with no anti-backflow valves or sterile components—using them for medical purposes can cause infection. Electric suction apparatuses have medical-grade hygiene and pressure control.

Suction Irrigation Units

Combine suction and fluid irrigation (e.g., for surgical cleaning)

Focus on “suction + irrigation” (e.g., flushing the surgical field while removing fluids), while standard electric suction apparatuses only provide suction. Irrigation units are more specialized for complex procedures.

VI. How to Choose a Suitable Electric Suction Apparatus?

Selecting an electric suction apparatus requires matching the device’s performance to specific use scenarios (e.g., medical vs. industrial, portable vs. stationary). Key factors to consider include:

1. Determine the Use Scenario

Medical Clinical Use: Prioritize models with adjustable pressure range (20-100 kPa), anti-backflow design, and sterilizable components (e.g., stainless steel collection containers). Look for certifications like CE (European Union) or FDA (U.S.) to ensure compliance with medical standards—similar to the quality controls Jiangyin Jianshifu applies to its disinfection equipment.

Home Care or Emergency Use: Choose portable models (weight <5kg) with rechargeable batteries (battery life ≥4 hours) and simple controls (one-button operation) for easy use by caregivers.

Industrial Use: Select high-pressure models (100-200 kPa) with large-capacity collection containers (≥20L) for handling heavy-duty waste (e.g., oil, metal shavings).

2. Check Core Performance

Negative Pressure Stability: The device should maintain consistent pressure (fluctuation ≤5 kPa) during use—unstable pressure can affect suction efficiency or cause tissue damage.

Noise Level: For medical settings (e.g., patient wards), choose low-noise models (<60 dB) to avoid disturbing patients. Industrial models may have higher noise levels (acceptable for workshops).

Battery Life (for Portable Models): Ensure the battery can support continuous use for at least 3-4 hours—critical for emergency rescue or home care without power outlets.

3. Focus on Safety and Maintenance

Safety Features: Look for overload protection (auto-shutdown if the motor overheats), low-battery alarm (for portable models), and easy-to-read pressure gauges (to avoid operational errors).

Maintenance Convenience: Choose models with detachable components (e.g., collection containers, filters) for easy cleaning. Reusable parts should be compatible with common disinfection methods (e.g., autoclaving, chemical disinfection).

4. Consider Brand and After-Sales Support

Select manufacturers with experience in medical or industrial equipment. Companies like Jiangyin Jianshifu Equipment Co., Ltd.—with a track record in producing medical-grade disinfection devices—understand the importance of after-sales service (e.g., maintenance guidance, replacement parts supply), which is crucial for long-term device reliability. Avoid “no-name” products with no safety certifications or service guarantees.

VII. Key Points for Maintenance of Electric Suction Apparatuses?

Proper maintenance extends the device’s lifespan, ensures stable performance, and reduces safety risks. Follow these guidelines:

1. Regular Cleaning and Disinfection

After Each Use (Medical Models): Disassemble the collection container, suction tube, and probe (if reusable). Clean them with warm water and neutral detergent, then disinfect with medical-grade disinfectant (e.g., 75% alcohol for plastic parts, autoclaving for metal parts). Dry thoroughly before reassembly to prevent mold growth.

Weekly Inspection: Check the vacuum pump’s filter—replace it if it is clogged with dust or fluid residues (clogged filters reduce suction force and damage the motor).

2. Motor and Power Maintenance

Lubrication (for Oil-Free Pumps): Do not add oil—oil-free pumps are maintenance-free. For oil-lubricated pumps (industrial models), check the oil level monthly and replace the oil with the manufacturer-specified type when it turns dark.

Power Cord and Battery Care: Avoid bending the power cord excessively to prevent internal wire damage. For portable models, charge the battery after each use (do not overcharge for more than 12 hours) to extend battery life.

3. Long-Term Storage

Store the device in a dry, cool place (temperature 5-30℃, humidity <60%) away from direct sunlight or corrosive substances (e.g., chemicals).

For models not used for more than 3 months, charge the battery to 50% (for portable models) and run the device for 10 minutes monthly to keep the motor active.

4. Professional Servicing

Schedule annual maintenance by the manufacturer or authorized service providers (e.g., Jiangyin Jianshifu’s after-sales team for its equipment). Professionals will test pressure accuracy, inspect the motor, and replace worn parts (e.g., diaphragms in the vacuum pump) to ensure the device meets safety standards.

VIII. How Does Jiangyin Jianshifu Equipment Co., Ltd. Relate to Electric Suction Apparatuses?

While Jiangyin Jianshifu Equipment Co., Ltd. is primarily known for disinfection equipment (e.g., plasma air sterilizers, bed unit sterilizers, UV germicidal lamps), its core competencies position it well to expand into electric suction apparatus manufacturing:

1. Shared Technical Expertise

The company’s experience in precision manufacturing (e.g., producing leak-proof disinfection equipment) and medical-grade safety design (e.g., ensuring sterility in bed unit sterilizers) aligns with the requirements of medical electric suction apparatuses—such as anti-backflow valves, pressure control systems, and sterile components. Its professional modernized production lines and testing equipment can be adapted to produce electric suction apparatuses that meet clinical standards.

2. Complementary Product Portfolio

For healthcare customers (e.g., hospitals, clinics) that already use Jiangyin Jianshifu’s disinfection equipment, adding electric suction apparatuses allows the company to offer a “disinfection + patient care” one-stop solution. This enhances customer loyalty and expands its market presence in the medical equipment sector.

3. Established Service Network

The company’s existing services—including requirements analysis and consultation (helping customers select suitable models), installation and commissioning (for stationary clinical models), and after-sales support (maintenance, spare parts supply)—can be directly applied to electric suction apparatuses. This ensures customers receive consistent, high-quality service across all product lines.

In summary, Jiangyin Jianshifu’s expertise in medical equipment safety, precision manufacturing, and customer service makes it a credible potential provider of electric suction apparatuses—extending its commitment to meeting diverse healthcare needs.

English

English  عربى

عربى

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China sara@jsf-qx.com

sara@jsf-qx.com +86-18915253915

+86-18915253915 +86-18861287595

+86-18861287595