In daily life and industrial production, water safety is a crucial issue, and UV Water Sterilizer (ultraviolet water sterilizer) has become a common equipment to ensure water quality due to its efficient and pollution-free characteristics. However, there are still many doubts about this equipment in actual application. The following will answer these questions one by one combined with practical industry knowledge.

1. Core Principle: How does UV Water Sterilizer realize water disinfection? Will it change the chemical composition of water?

The core disinfection principle of UV Water Sterilizer is similar to that of UV Lamp Sterilizer Trolley, which relies on the UVC band ultraviolet rays (wavelength 200-280nm) emitted by the ultraviolet lamp. When water flows through the disinfection chamber of the equipment, the UVC ultraviolet rays will penetrate the cell membrane of microorganisms (such as bacteria, viruses, protozoa, etc.) in the water, destroy their DNA or RNA structure, making them lose the ability to reproduce and infect, thus achieving the purpose of killing microorganisms in water.

A major advantage of this disinfection method is that it does not require adding any chemical disinfectants (such as chlorine, ozone, etc.) to the water. Therefore, it will not change the chemical composition of the water itself, nor will it produce harmful by-products (such as trihalomethanes generated by chlorine disinfection). After disinfection, the water will not have peculiar smell or taste, and can maintain the original physical and chemical properties of the water. This is particularly important for scenarios that have high requirements for water quality, such as drinking water treatment, food processing water, and pharmaceutical industry water.

2. Applicable Scenarios: Which fields are suitable for using UV Water Sterilizer? Are there any restrictions on the water quality to be treated?

UV Water Sterilizer has a wide range of applications, covering daily life, industrial production, medical and health care and other fields. In daily life, it is often used for the disinfection of household drinking water (such as matching with water purifiers), swimming pool water, and bathing water, to prevent microorganisms in water from endangering human health. In the industrial field, it is widely used in food processing (such as beverage production, aquatic product processing, dairy product processing) to ensure the safety of production water; in the pharmaceutical industry, it is used for the disinfection of pharmaceutical water to meet the strict hygiene standards of the pharmaceutical industry; in the aquaculture industry, it can disinfect aquaculture water, reduce the occurrence of diseases of aquatic organisms, and improve the survival rate of aquatic products.

However, UV Water Sterilizer has certain restrictions on the water quality to be treated. First, the turbidity of water is a key factor. If the water contains too many suspended solids, these substances will block the penetration of ultraviolet rays, making it impossible for ultraviolet rays to fully act on microorganisms in the water, thus reducing the disinfection effect. Generally, the turbidity of water to be treated by UV Water Sterilizer should be controlled below 5 NTU. Second, the content of organic matter in water will also affect the disinfection effect. Excessive organic matter will absorb ultraviolet rays, and may react with ultraviolet rays to form some substances that affect water quality. In addition, if the water contains heavy metal ions or other impurities that can absorb ultraviolet rays, it will also reduce the disinfection efficiency of the equipment. Therefore, before using UV Water Sterilizer, it is usually necessary to pre-treat the water (such as filtration, precipitation) to ensure that the water quality meets the treatment requirements of the equipment.

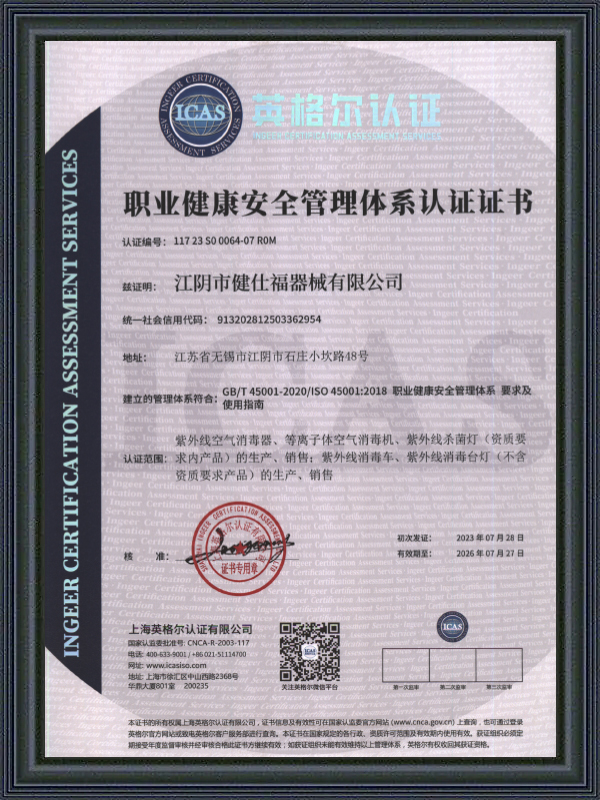

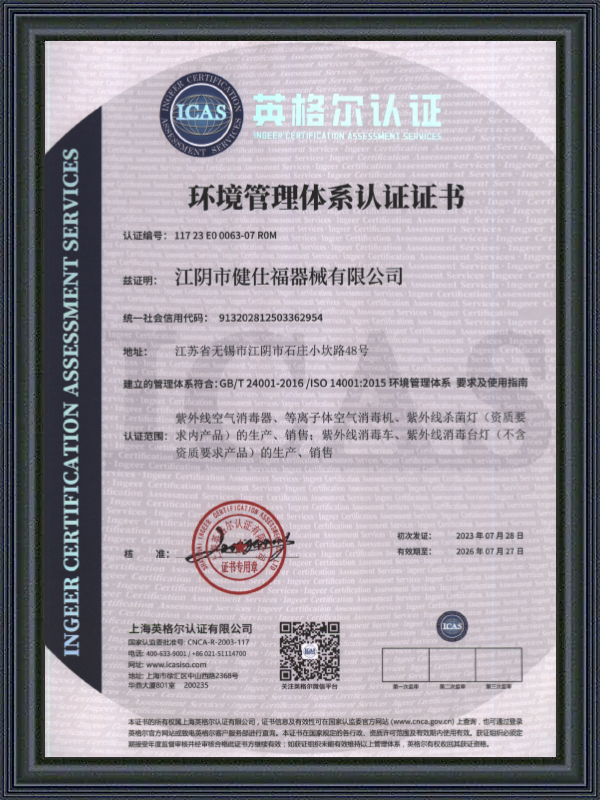

Enterprises like Jiangyin Jianshifu Equipment Co., Ltd., which have rich experience in the disinfection equipment industry and a complete product series, not only produce UV Lamp Sterilizer Trolley and other air disinfection equipment, but also can provide UV Water Sterilizer suitable for different scenarios according to the actual water quality and disinfection needs of customers. At the same time, they can also provide professional pre-treatment suggestions for water quality to ensure the disinfection effect of the equipment.

3. Purchase Points: What key indicators should be paid attention to when purchasing UV Water Sterilizer? How to choose the right equipment model?

When purchasing UV Water Sterilizer, many people do not know how to start. In fact, focusing on several key indicators can help you select suitable equipment. The first is the ultraviolet dose (unit: mJ/cm²), which is the product of the intensity of ultraviolet rays and the irradiation time. It is the core indicator to measure the disinfection effect of UV Water Sterilizer. Different microorganisms have different requirements for the minimum ultraviolet dose to be killed. For example, the minimum dose required to kill common Escherichia coli is about 6-15 mJ/cm², while the dose required to kill Cryptosporidium is higher, about 40 mJ/cm². Therefore, when purchasing, you should select the equipment with appropriate ultraviolet dose according to the types of microorganisms to be treated in the water.

The second is the water treatment flow rate (unit: L/h or m³/h), which refers to the amount of water that the equipment can disinfect per unit time. When selecting, it is necessary to match the flow rate of the equipment with the actual water consumption. If the flow rate of the equipment is too small, it will not meet the water demand of the user; if the flow rate is too large, the water will stay in the disinfection chamber for too short a time, and the ultraviolet irradiation time will be insufficient, resulting in incomplete disinfection. For example, for a family with 3-4 people, the daily drinking water consumption is about 10-20 L, so a UV Water Sterilizer with a flow rate of 100-200 L/h can meet the demand; for a small beverage factory with a daily water consumption of 50 m³, it is necessary to select equipment with a flow rate of more than 2 m³/h.

The third is the quality of the ultraviolet lamp. The service life and ultraviolet intensity of the ultraviolet lamp directly affect the service life and disinfection effect of the equipment. At present, the common ultraviolet lamps on the market include low-pressure mercury lamps and medium-pressure mercury lamps. Low-pressure mercury lamps have the advantages of long service life (usually 8000-12000 hours) and stable ultraviolet output, which are suitable for small and medium flow water treatment scenarios; medium-pressure mercury lamps have high ultraviolet intensity and large treatment flow, but their service life is relatively short (usually 2000-4000 hours), which are suitable for large flow industrial water treatment. When purchasing, you can ask the manufacturer about the type, service life and replacement cycle of the ultraviolet lamp.

In addition, when choosing the equipment model, you also need to consider the installation environment and water quality characteristics. For example, if the installation space is limited, you can choose a compact UV Water Sterilizer; if the water contains more impurities, you should choose the equipment with a pre-filter or a more durable quartz sleeve (the quartz sleeve is used to protect the ultraviolet lamp and prevent water from contacting the lamp directly). Enterprises like Jiangyin Jianshifu Equipment Co., Ltd. can provide professional product consultation and recommendations. They will conduct in-depth communication with customers to understand their specific water demand, water quality conditions and application scenarios, and help customers select the most suitable UV Water Sterilizer model.

4. Usage Specifications: How to install UV Water Sterilizer correctly? What should be paid attention to during use?

Correct installation and use are the prerequisites for ensuring the normal operation and disinfection effect of UV Water Sterilizer. In terms of installation, first of all, the installation position should be selected reasonably. The equipment should be installed after the water pre-treatment system (such as filter, water softener) to avoid impurities in the water adhering to the quartz sleeve and affecting the ultraviolet transmittance. At the same time, the installation position should be far away from high-temperature, high-humidity and corrosive environments to prevent damage to the equipment.

Secondly, the connection of the water pipeline should be correct. The water inlet and outlet of the equipment must not be reversed. Otherwise, the water will not flow through the disinfection chamber normally, and the equipment will not work. After the pipeline connection is completed, it is necessary to conduct a pressure test to check whether there is water leakage at the connection. In addition, if the equipment is used for drinking water disinfection, the pipeline materials should comply with the national drinking water hygiene standards to avoid secondary pollution of water.

During use, there are also many points to pay attention to. First, it is necessary to ensure that the equipment is powered on normally. The ultraviolet lamp needs to work under a stable voltage. If the voltage is unstable, it may affect the intensity of ultraviolet rays or even damage the lamp. Some high-quality UV Water Sterilizers are equipped with voltage stabilization devices, which can effectively avoid the impact of voltage fluctuations. Second, it is necessary to regularly check the operation status of the equipment. Most UV Water Sterilizers are equipped with indicator lights or display screens, which can show the working status of the ultraviolet lamp (such as normal operation, lamp failure, etc.). If the fault indicator light is on, it is necessary to stop using the equipment immediately and check the cause (such as lamp damage, power failure, etc.).

In addition, it should be noted that UV Water Sterilizer is only used to kill microorganisms in water, and cannot remove impurities such as heavy metals, organic matter, and turbidity in water. Therefore, it cannot replace water purifiers or other water treatment equipment. If the raw water quality is poor, it is necessary to use UV Water Sterilizer together with other water treatment equipment to ensure the safety and quality of water.

5. Maintenance and After-sales: How to maintain UV Water Sterilizer daily? What should be done if the equipment fails?

Daily maintenance of UV Water Sterilizer can not only extend the service life of the equipment, but also ensure its long-term stable disinfection effect. The most important maintenance work is to clean the quartz sleeve regularly. During the use of the equipment, impurities such as scale, algae, and microorganisms in the water will adhere to the outer surface of the quartz sleeve, forming a dirt layer. This dirt layer will block the penetration of ultraviolet rays, reducing the disinfection effect. The cleaning cycle depends on the water quality. For water with high hardness (easy to scale), it is recommended to clean it once every 1-2 months; for water with good quality, it can be cleaned once every 3-6 months. When cleaning, first cut off the power supply of the equipment, remove the quartz sleeve, and wipe the surface with a soft cloth or sponge (do not use hard objects to scratch the surface to avoid damaging the quartz sleeve). If there is stubborn scale, you can soak the quartz sleeve in a dilute citric acid solution for 10-20 minutes, then wipe it clean and reinstall it.

The second maintenance work is to replace the ultraviolet lamp regularly. As the use time increases, the intensity of the ultraviolet lamp will gradually decrease. When the intensity is lower than the minimum effective value (usually 70% of the initial intensity), even if the lamp is still on, it cannot achieve the expected disinfection effect. At this time, the lamp must be replaced in time. The replacement cycle of the lamp should be determined according to the service life of the lamp indicated in the product manual. Generally, low-pressure mercury lamps need to be replaced every 1-2 years, and medium-pressure mercury lamps need to be replaced every 6-12 months. When replacing the lamp, it is necessary to select the lamp of the same model and specification as the original one to ensure the matching of the equipment.

In terms of after-sales service, if the equipment fails during use (such as no ultraviolet output, water leakage, abnormal noise, etc.), do not disassemble the equipment by yourself. You should first cut off the power supply and water source of the equipment, then contact the manufacturer or its authorized after-sales service provider for maintenance. Enterprises like Jiangyin Jianshifu Equipment Co., Ltd. provide comprehensive after-sales service and technical support. They can provide remote guidance for simple faults (such as lamp replacement, quartz sleeve cleaning), and send professional technicians to on-site maintenance for complex faults. At the same time, they also provide operational training and guidance for customers, helping customers master the correct use and maintenance methods of the equipment.

In addition, it is also necessary to pay attention to the calibration of the ultraviolet intensity detector (if the equipment is equipped with one). The intensity detector is used to monitor the intensity of the ultraviolet lamp in real time. If the detector is inaccurate, it will affect the judgment of the equipment's disinfection effect. It is recommended to calibrate the detector once every 1-2 years to ensure its accuracy.

English

English  عربى

عربى

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China

No 48 Xiaokan Rd, Shizhuang town, Jiangyin, Jiangsu, China sara@jsf-qx.com

sara@jsf-qx.com +86-18915253915

+86-18915253915 +86-18861287595

+86-18861287595